February 25, 2025

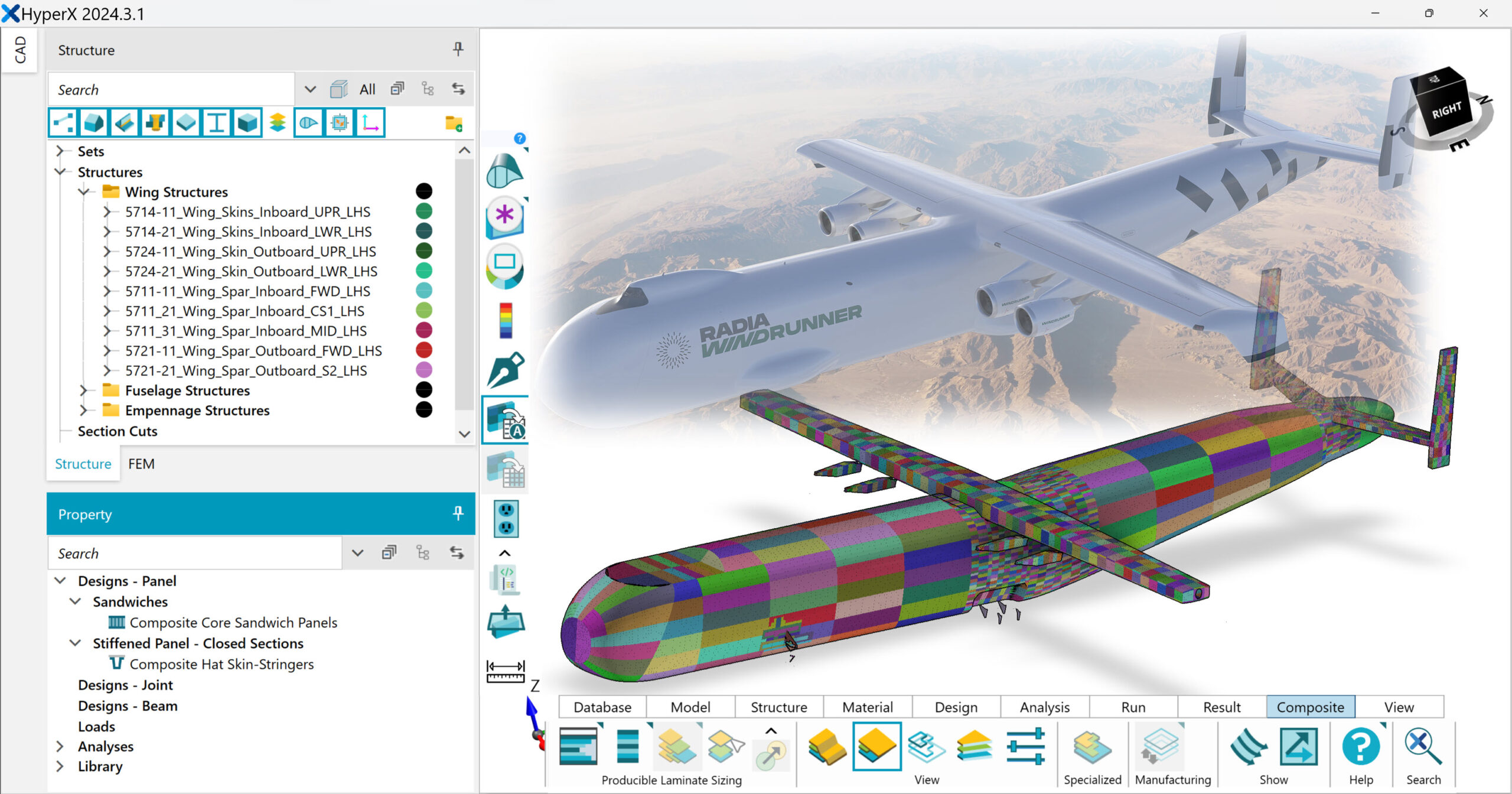

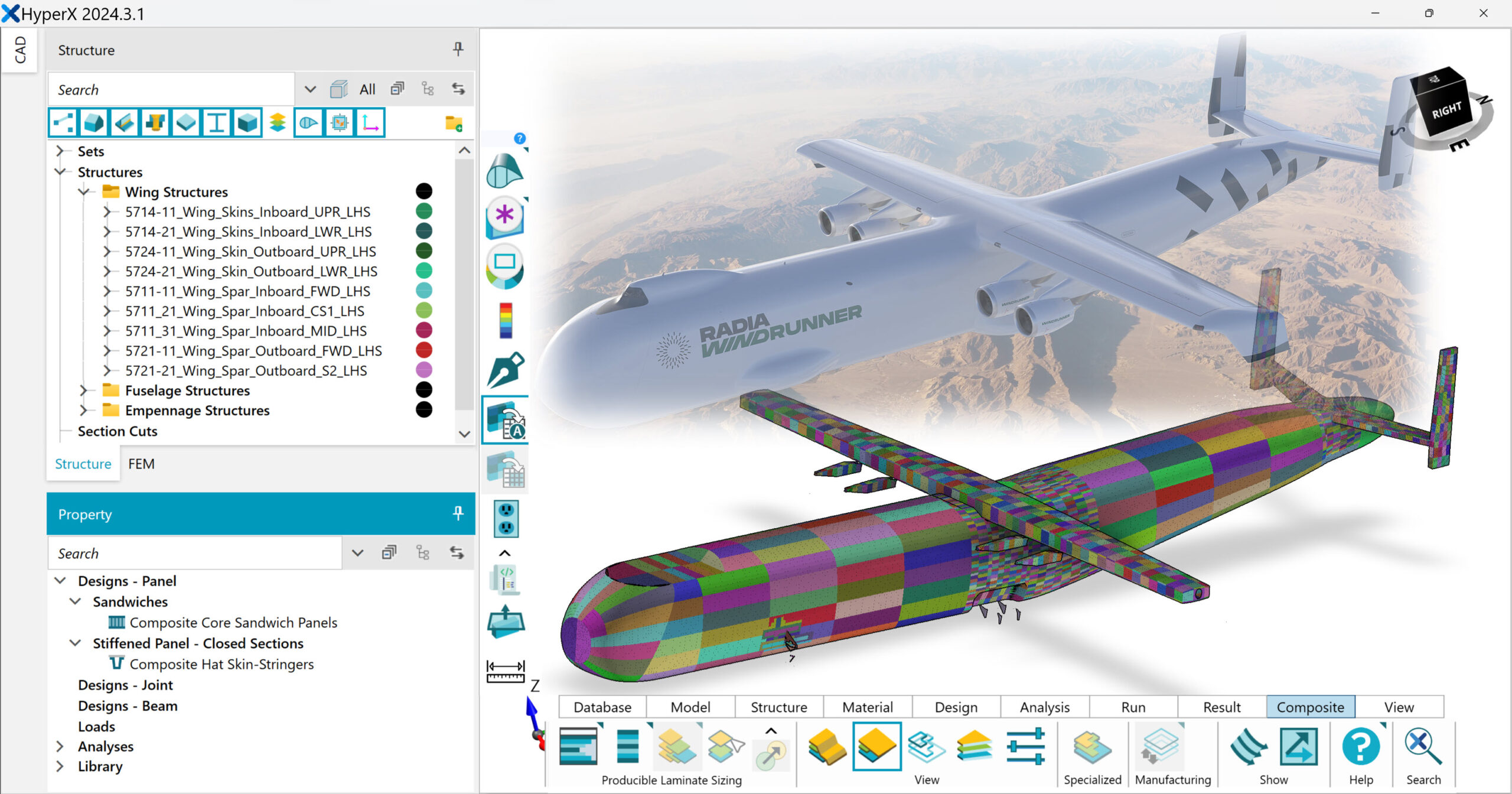

Artist rendering of the WindRunner airframe model showing optimization zones in HyperX software interface. Photo credit Collier Aerospace Corp.

NEWPORT NEWS, Va. — Collier Aerospace Corp., developer of the HyperX® computer-aided engineering (CAE) solution, today announced that Radia, Inc. selected its design and analysis software for the structural sizing of WindRunner™ – the world’s largest aircraft. Structural sizing is the critical process of determining the size and weight of primary aircraft structures.

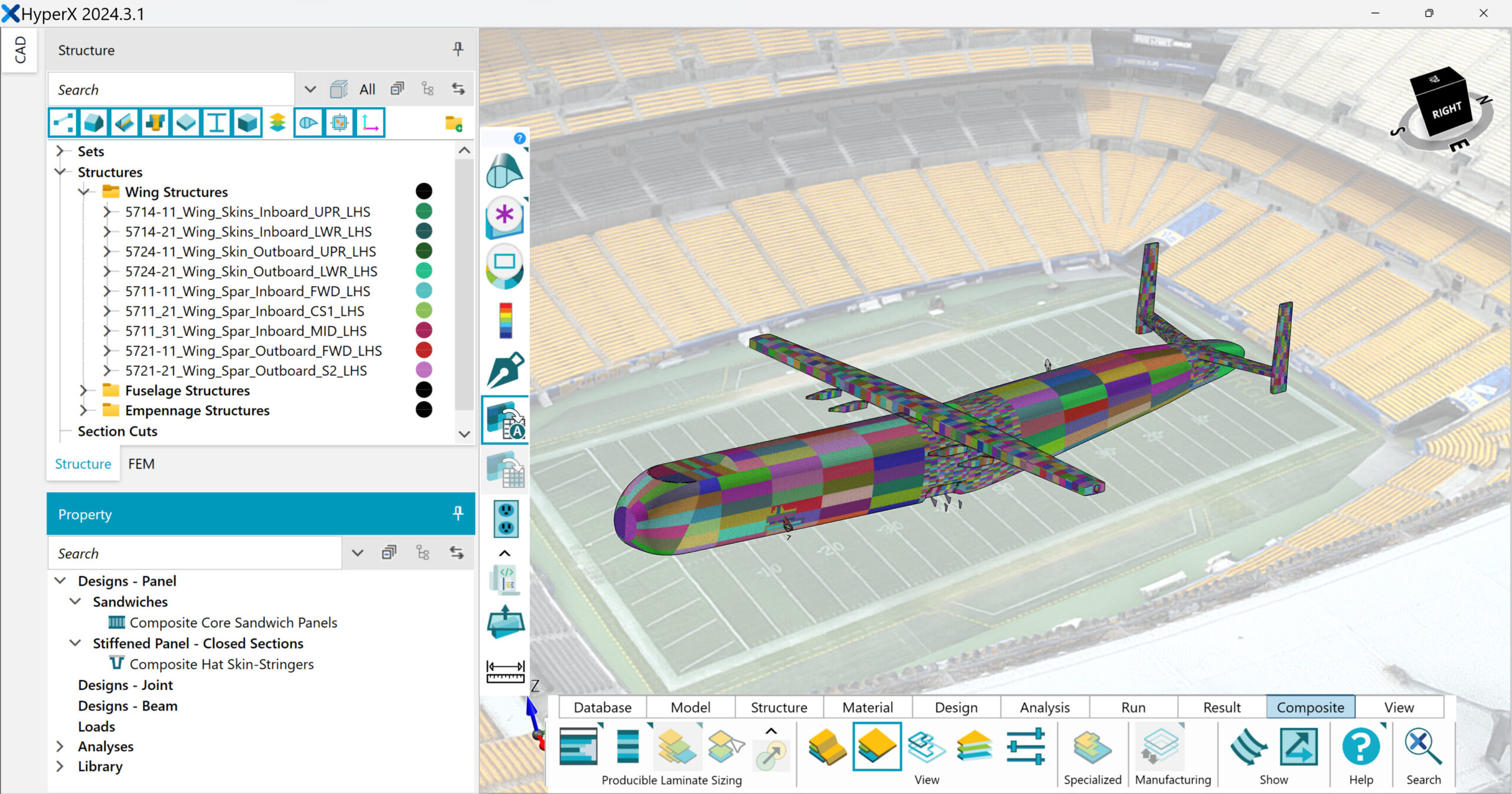

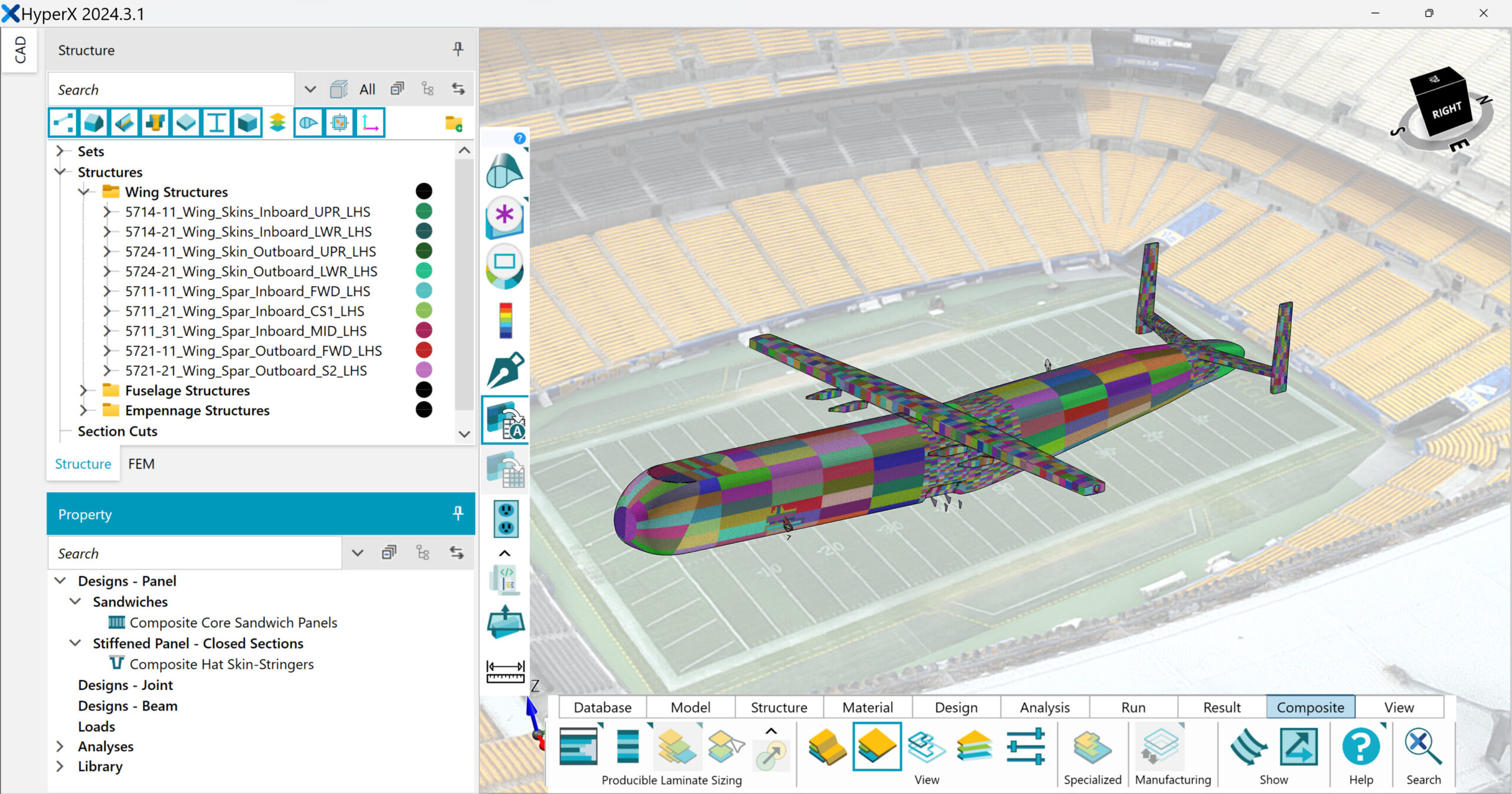

Boulder, Colorado-based Radia is developing the WindRunner aircraft, an outsized aerial logistics platform designed to efficiently and effectively deliver the world’s largest cargo, such as wind energy turbine blades, spacecraft, satellites, defense cargo, airplanes and large commercial payloads. WindRunner solves transportation bottlenecks with its ability to fly cargo that is up to the length of a football field, and land on semi-prepared dirt runways as short as 1,800m (6,000 ft), when required.

Collier Aerospace’s software and services help Radia’s engineering and design teams optimize and accelerate sizing for the massive aircraft’s airframe and efficiently evaluate and analyze many different design configurations under rigorous time and cost pressures.

“Using Collier’s technology, we can create and analyze design concepts in hours and automate the time-consuming process of evaluating hundreds to thousands of load cases,” said Mark Lundstrom, founder and CEO of Radia. “Collier’s software helps us efficiently evaluate design options and optimize WindRunner’s weight and structural performance in support of its critically important mission.”

Radia began the WindRunner project in 2016 and brought in Collier Aerospace at an early stage as a software provider and engineering consultant. Using Collier’s methodology for structural sizing and analysis, Radia built a customized design process for the new aircraft’s unique requirements. The team conducted configuration assessments of the wings, fuselage, ribs, spars, stringers and many other parts, which will be made of both composite and metal. Radia leveraged the tool’s automated sizing capabilities to account for unusual variables such as the huge size and capacity of the unpressurized fuselage.

HyperX® software automates stress analysis and design. It performs rapid structural sizing to all load cases, lightweighting and margin writing. The software also helps ensure the producibility of a composite part by creating a design that is optimized for manufacturability. It reduces schedule time by speeding up the engineering cycle and shortening the U.S. Federal Aviation Administration (FAA) and European Union Aviation Safety Agency (EASA) certification processes.

“It’s been a thrill to work with Radia on its breakthrough WindRunner aircraft and contribute to its extraordinary mission,” commented Craig Collier, professional engineer and CEO of Collier Aerospace. “This collaboration brought together the vision of the Radia team and our collective deep knowledge and experience in aerospace structural engineering. We contributed to the success of this design project by providing guidance on our software’s capabilities. We can’t wait to see the final result of this groundbreaking design when WindRunner makes its maiden flight.”

Radia plans to build a fleet of WindRunner aircraft that will enable manufacturers to transport their largest products across the globe.

Artist rendering showcasing the WindRunner aircraft, approximately the length of a football field (356 ft), shown in HyperX software interface. Photo credit Collier Aerospace Corp.

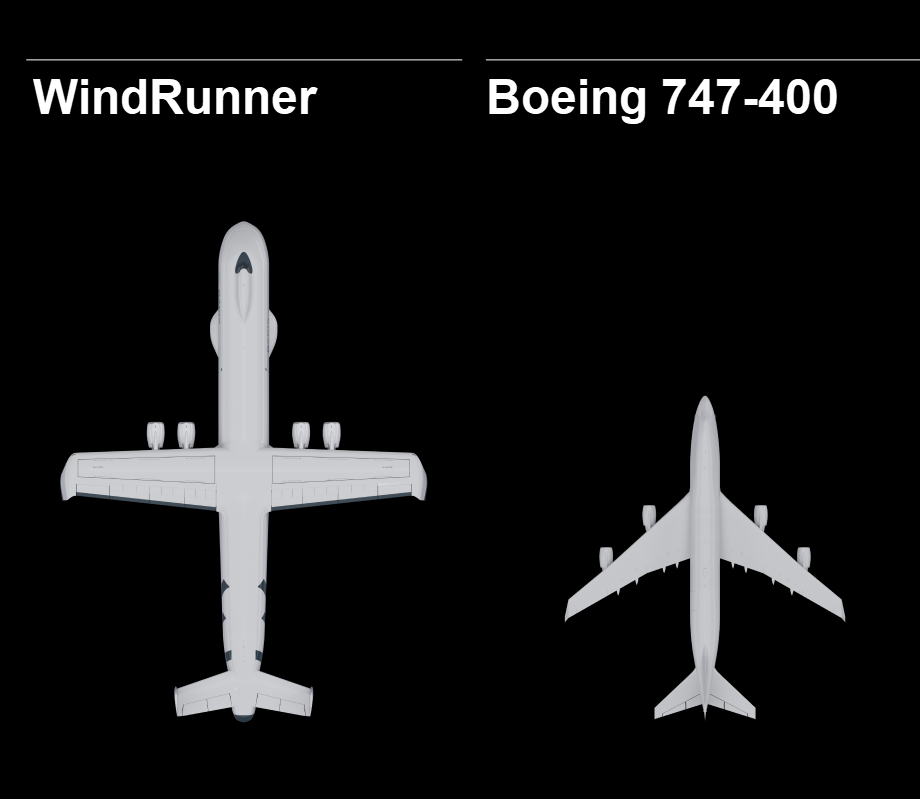

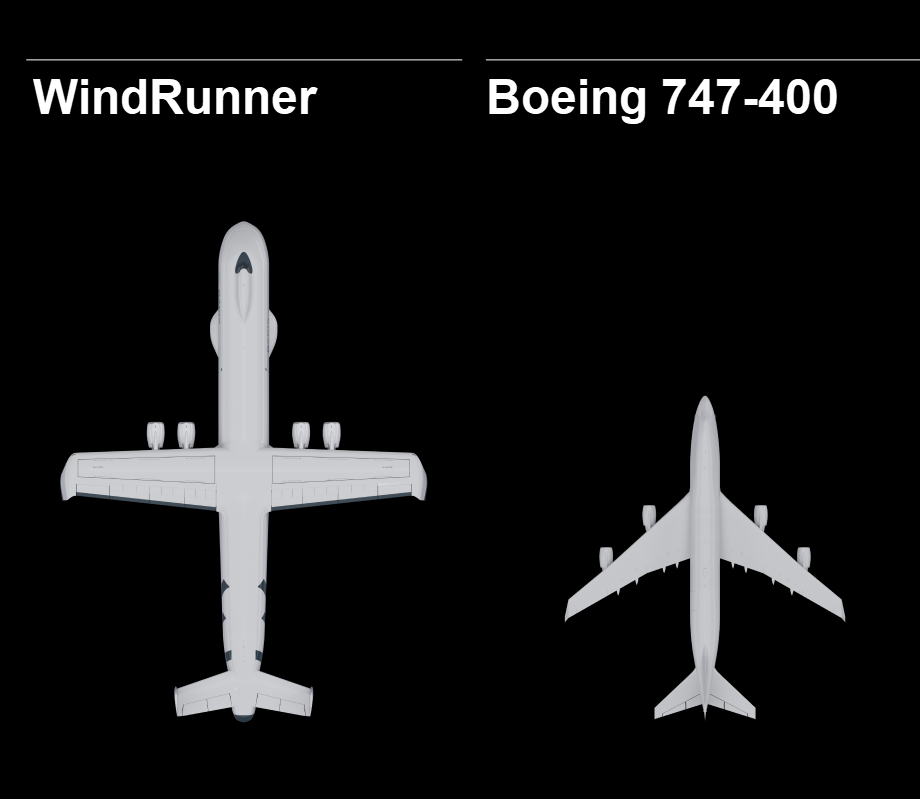

Aircraft size comparison of the WindRunner and a Boeing 747-400. Photo credit Radia.

ABOUT Collier Aerospace

Collier Aerospace Corporation is a leading provider of computer-aided engineering (CAE) software for designing composite and metallic structures. Its flagship product, HyperX® software, is a structural solution for failure analysis, stress reporting, design sizing optimization and data traceability. It is used across multiple industries: aerospace, space launch, automotive, wind energy and high-performance sports. The software helps designers and engineers reduce weight, accelerate development, improve design producibility and achieve airframe certification. The company was founded in 1995 by engineers Craig and Ivonne Collier and is headquartered in Newport News, Va. Learn more at https://collieraerospace.com.

HyperX® is a registered trademark of Collier Aerospace Corportaion.