Click here to Read Aerospace Manufacturing Article

July 28, 2025

Written By Mike Richardson

Craig Collier, founder, president & CEO of design and analysis software specialists, Collier Aerospace explains how the company’s products can help aerospace engineers solve multiple part design challenges.

When comparing potential part designs, aerospace engineers need to consider the trade-offs between weight and manufacturability due to variations in size. Consider an aircraft wing for example.

To account for differences in loading, there may be many variations in sizing dimensions such as stiffener spacing, height, and flange width from panel to panel. As a result, the wing may weigh less, but it will be more difficult to manufacture. Conversely, a wing design without many panel-to-panel variations would be easier to produce, but heavier.

To avoid production issues, design for manufacturability (DFM) is a key consideration. For smaller aircraft, wings that are made of composite materials can have a sandwich-like structure where each panel bay has a different core material and thickness. This approach supports lightweighting, but it is difficult and more expensive to machine each panel to its own core height and to an ideal core material cell size.

Aerospace engineers use computer-aided engineering (CAE) software to design an airframe structure with size and weight in mind; however, users often find that traditional software is time-consuming and does not allow for design space exploration. Many optimisation tools provide just a single design, and that makes it more difficult for engineers to improve their structures. As such, the manufacturer may not fully understand the trade-off of weight versus manufacturability.

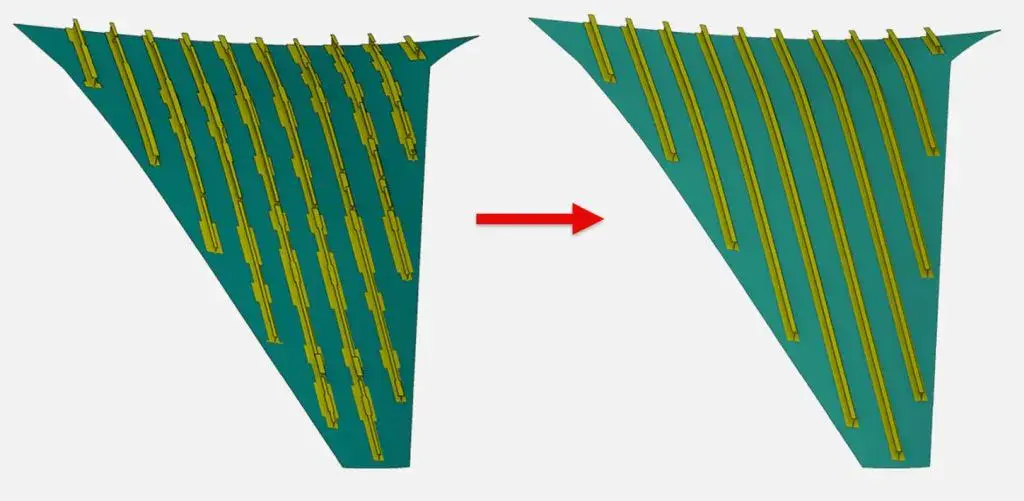

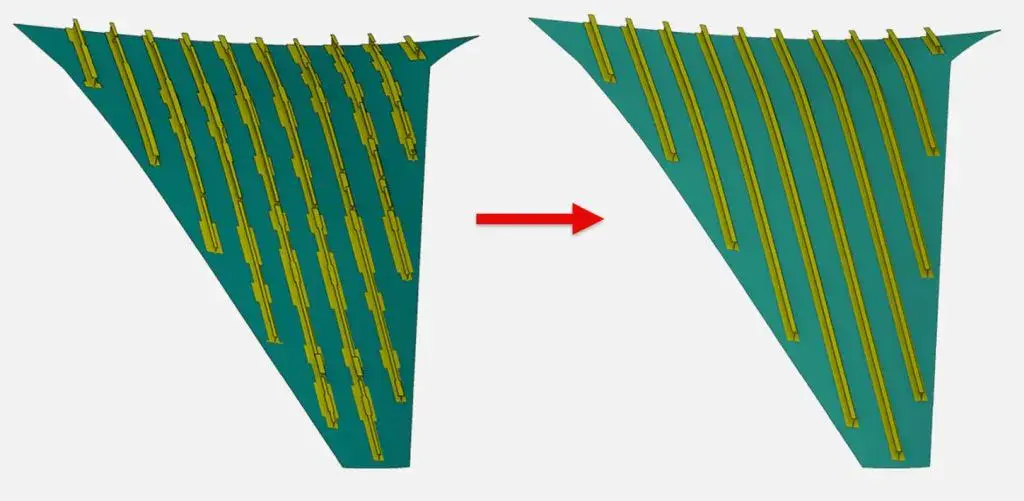

HyperXpert displays the ‘before’ variation of stringer profiles (left). The improved ‘after’ profile (right) indicates that the more cross-sectional dimensions are linked across a part, the easier that part is to manufacture

Once a design is selected, engineers need an efficient way to share this information. Most CAE software is not aerospace-specific; therefore, the ability to generate a stress report for a preliminary and critical design review is not available. Clear and effective reporting is critical when it comes to providing regulatory agencies with margin-of-safety calculations for airframe certifications.

Made for design optimisation

Collier Aerospace, a leading provider of CAE software for designing composite and metallic structures, is enabling aerospace engineers to solve all these challenges with its flagship product, HyperX software. This proven technology uses analytical aerospace methods to perform structural sizing, lightweighting and margin of safety calculations. More specifically, it uses a structure’s finite element analysis (FEA) results to perform sizing optimisation and, in turn, determine the lightest weight combination of materials and panel cross-sectional dimensions, including layup ply angles and stacking sequences.

With composite structures, this advanced software helps engineers to quickly evaluate design alternatives by considering trade-offs in ply-layup schedules and core panel and edge band thickness. From conceptual and preliminary design stages all the way to part release, the HyperX database becomes the one source of truth for sizing results and margin of safety.

In addition, the CAE software’s database establishes a digital thread and works with a variety of FEA and computer-aided design (CAD) software, such as Nastran, Abaqus, Optistruct, HyperMesh, Catia, 3DX, and NX CAD. Without having to resubmit the FEA results, the HyperX software can provide the lightest-weight design for all panels, load cases and failure criteria. The database also includes information about fasteners so that engineers can select the right ones and specify their optimal locations.

HyperX software also automates stress analysis and performs rapid structural sizing to all load cases, lightweighting and margin writing. This solution helps ensure the producibility of a composite part through a design that is optimised for manufacturability. In addition to accelerating the engineering cycle, the software can shorten the US Federal Aviation Administration (FAA) and European Union Aviation Safety Agency (EASA) certification processes by providing margin-of-safety reporting.

Design Insight Expertise

Aerospace engineers can also benefit from using HyperXpert, an advanced design tool developed by Collier Aerospace to extend the typical HyperX workflow. Among its advantages, HyperXpert provides access to all the possible, lightest-weight designs with positive margins, allowing the engineer to compare a design’s part weight and manufacturability. To accomplish this, an engineer first provides part surface information, a defined design space, and a set of failure criteria that the part needs to satisfy. HyperXpert then performs a full factorial design of experiments (DOE) using its high-performance computing and displays the best options for the design space in a weight-versus-size variation plot.

Collier Aerospace’s design and analysis software was chosen by Swift Engineering for structural sizing, analysis and test validation of the X-59 aircraft’s nose cone (Photo Credits: Lockheed Martin/NASA)

Unlike other approaches to experimental design, full factorial DOE analyses every combination of variables and determines the individual impact of each variable on the response. The engineer can decide which variables to link and quantify how they affect each other. Examples of variables include cross-sectional dimensions, materials and laminates across a part. The HyperXpert tool organises the data in a plot, allowing engineers to quickly compare results, understand trends and select the best design to manufacture.

By quantifying manufacturability considerations during the earliest conceptual design phases, companies can avoid unnecessary costs and accelerate project timetables. For example, an aircraft wing skin with a lot of variation in stiffener profile dimensions weighs less but is more difficult to manufacture. Conversely, consistent dimensions will simplify tooling and hence be easier to manufacture. The HyperXpert tool satisfies both weight and manufacturability simultaneously.

Consider the following example. Radia, an energy company, needed to perform structural sizing for the development of WindRunner, an oversize cargo aircraft. This unique aerial transportation solution is designed to deliver huge wind turbines with blades up to 100m in length to onshore wind farms, while avoiding the limitations of ground transportation. To develop the WindRunner aircraft, the company involved Collier Aerospace at an early stage as both a software provider and engineering consultant.

Using Collier Aerospace’s methodology for structural sizing and analysis to meet the aircraft’s unique requirements, the team conducted configuration assessments of the wings, fuselage, ribs, spars, stringers and many other parts, which will be made of both composite material and metal. Radia also leveraged Collier Aerospace’s automated sizing capabilities to account for unusual variables such as the huge size and capacity of the unpressurised fuselage. This enabled Radia to make significant progress quickly.

From conceptual and preliminary design stages all the way to part release, Collier Aerospace’s HyperX software and HyperXpert tool can help aerospace engineers solve multiple challenges, including how to select a design when there are trade-offs between weight, part variation and manufacturability.

HyperX® is a registered trademark of Collier Aerospace Corportaion.