Starting with a HyperX Company Database template a Project database is made. The project database inherits the company materials, fasteners, laminate families, selected analysis methods, and company analysis plugins.

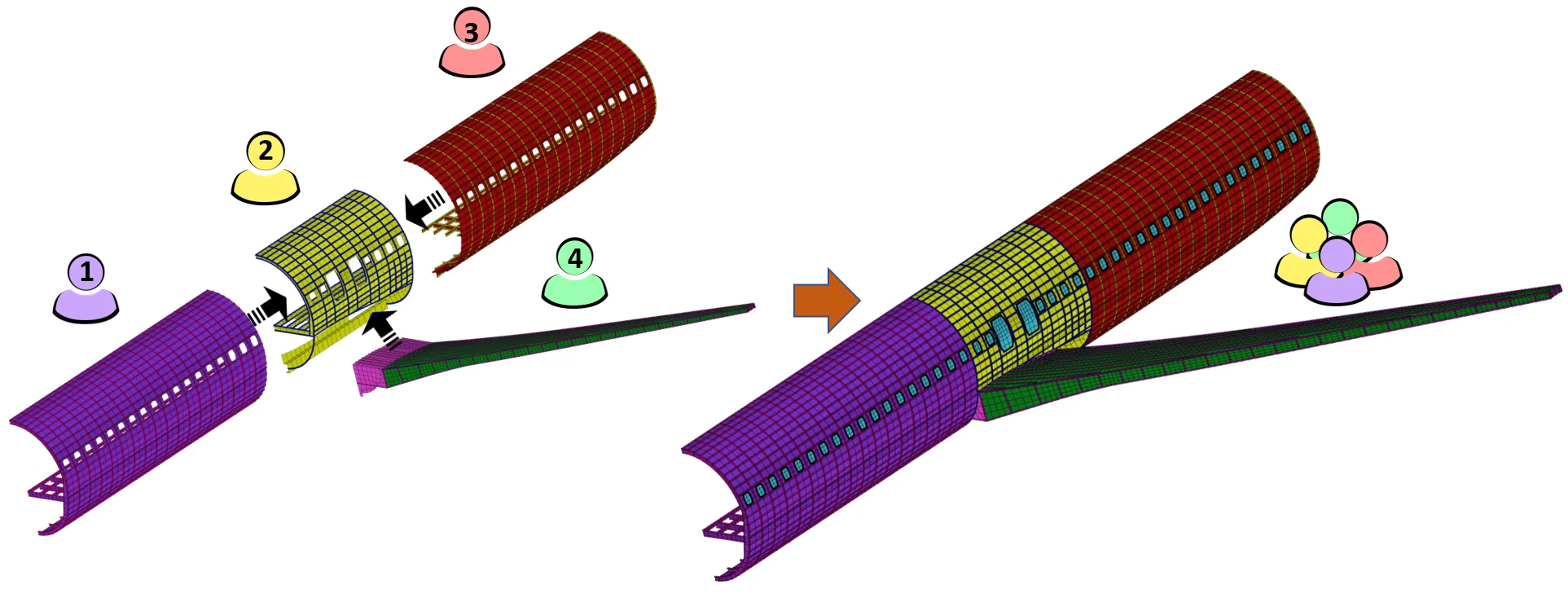

From the Project database, the Project Group Lead imports the GFEM and specifies FEA static and fatigue loads and load factors. Within this database, the Enterprise tool is then used to separate it into individual engineer databases.

The HyperX Enterprise utility provides the Project Group Lead with options regarding how to split the GFEM into individual databases, all of which inherit the group database settings and data. Moreover, the Enterprise utility allows the lead to specify data permissions: they can place certain locks on data, or authorize engineers to edit with changed-data tracking so that the sizing and analysis results cannot be rolled back into the Group database without the lead’s awareness and approval. Reports are made during the ‘roll back’ process for the Group Lead that identify data which has been potentially improperly modified.

This workflow allows each engineer to independently size their structure within their own database while still respecting program-level data and requirements. Once all structures have been sized and the results from each engineer’s database are rolled back into the parent database, an updated internal loads GFEM incorporating these results can be exported. At this time the GFEM can be rerun to generate loads paths consistent with the latest sizing results. This process can be repeated until GFEM loads converge and all parts are sufficiently sized – in a significantly shortened schedule!