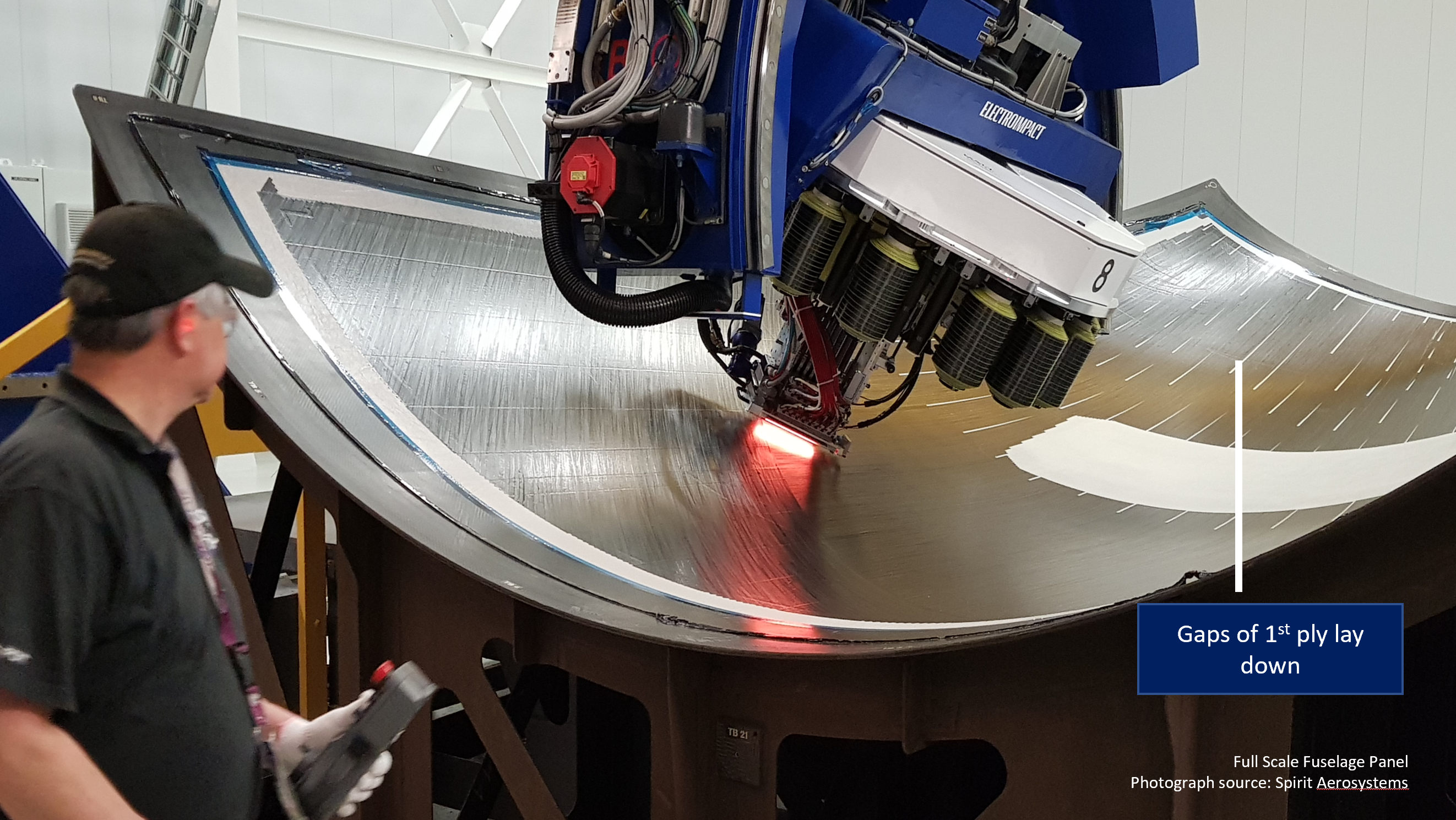

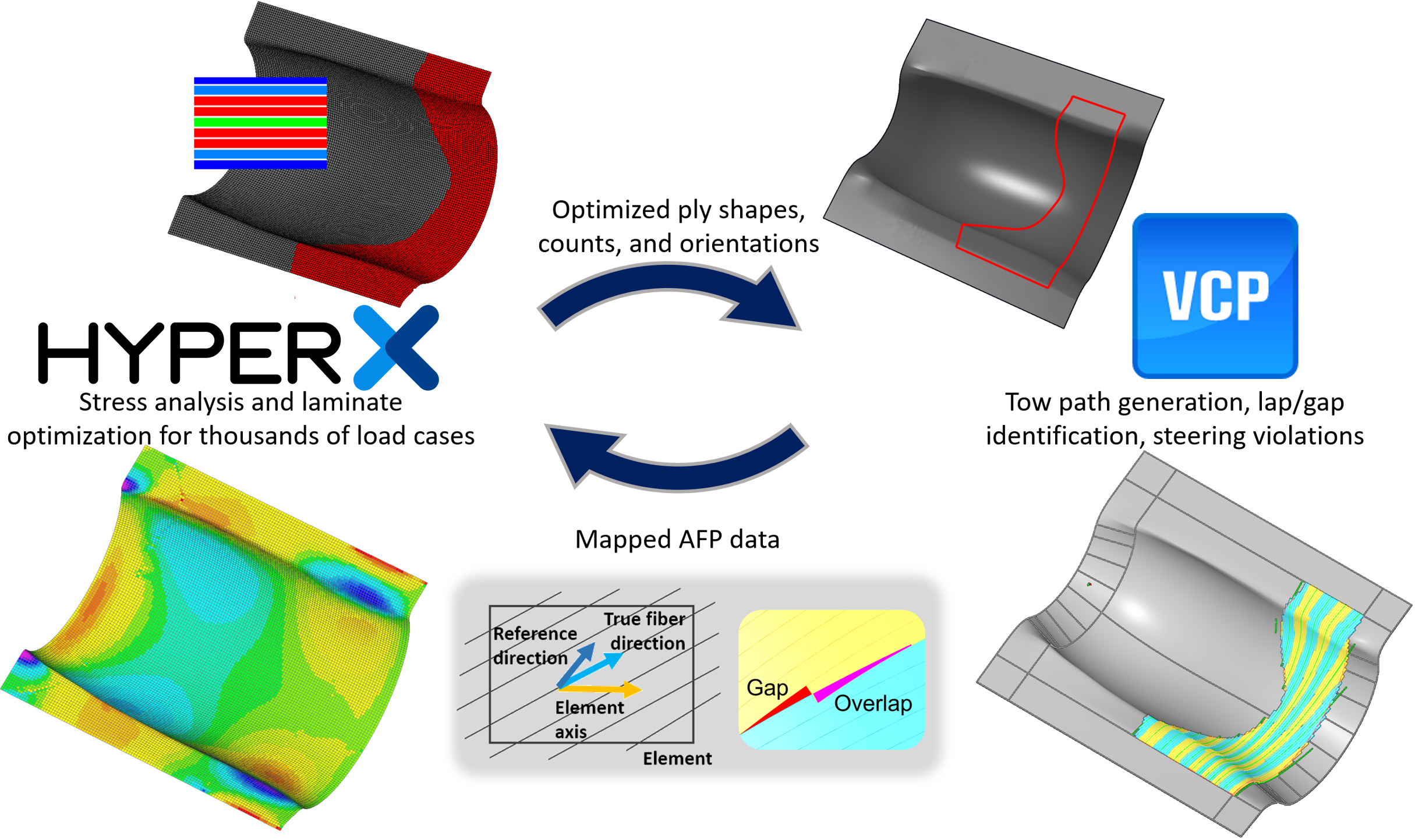

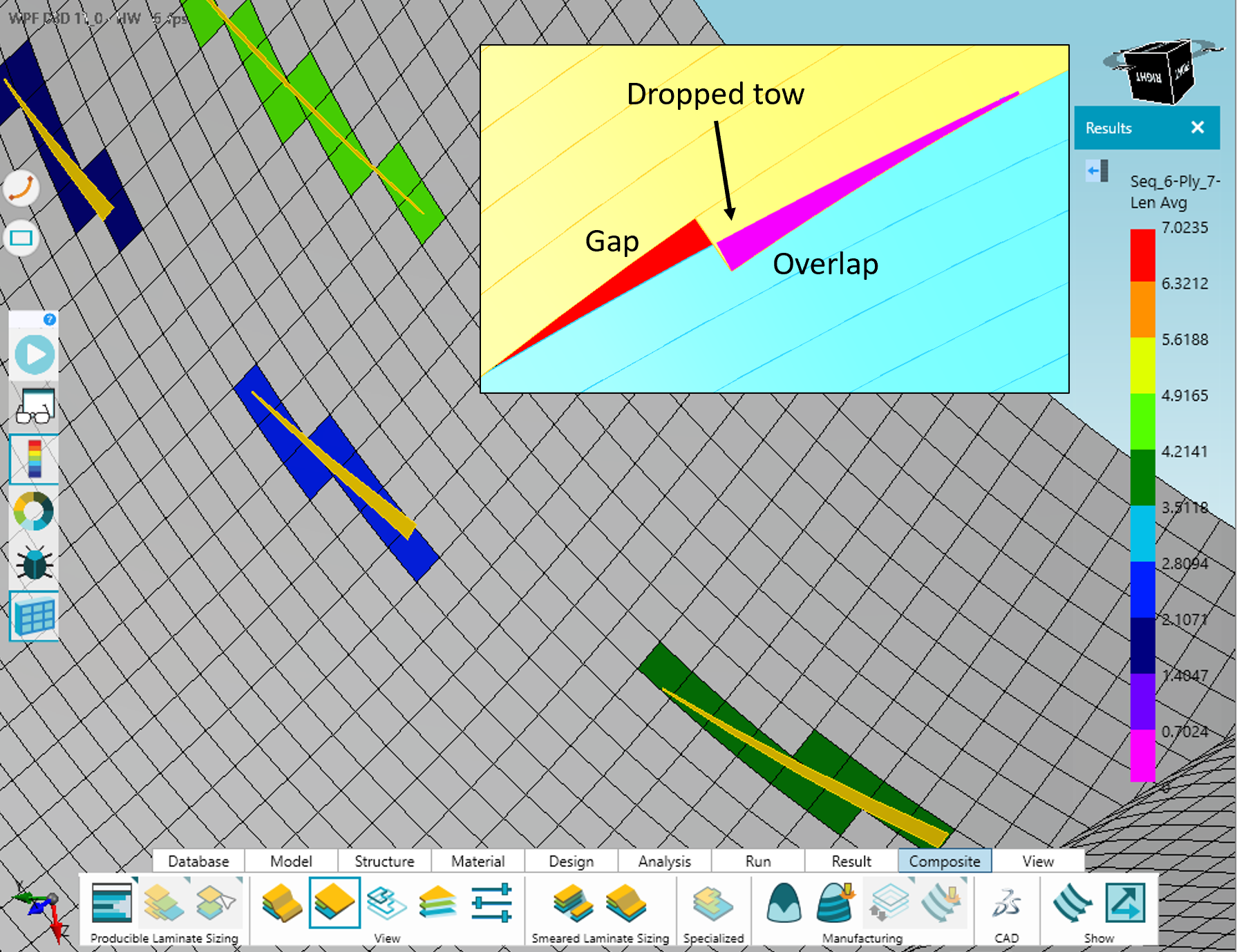

Although composites excel in applications with double curvature, manufacturing with Automated Fiber Placement (AFP) can introduce challenges with fiber alignment and overlaps and gaps (of individual tows in plies).

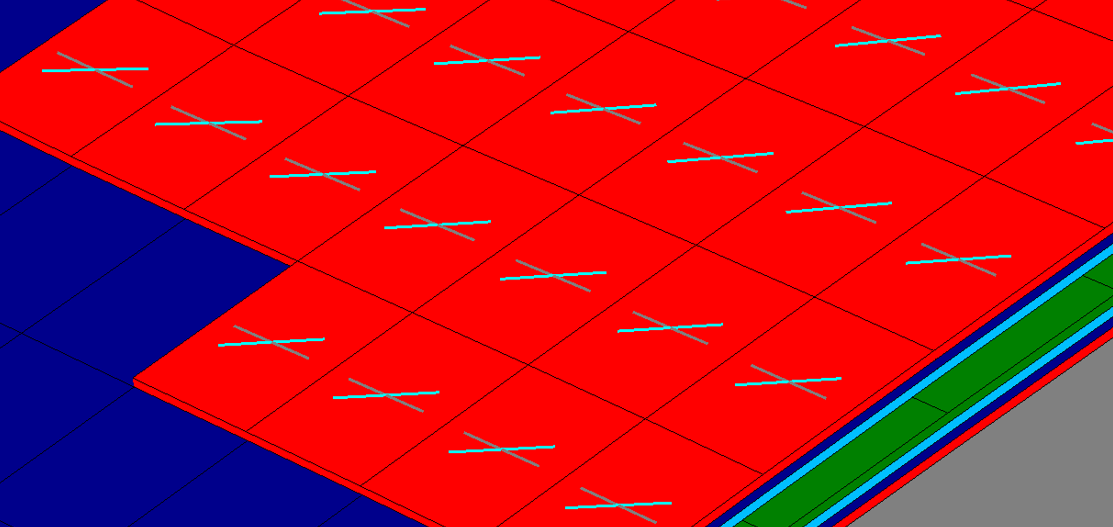

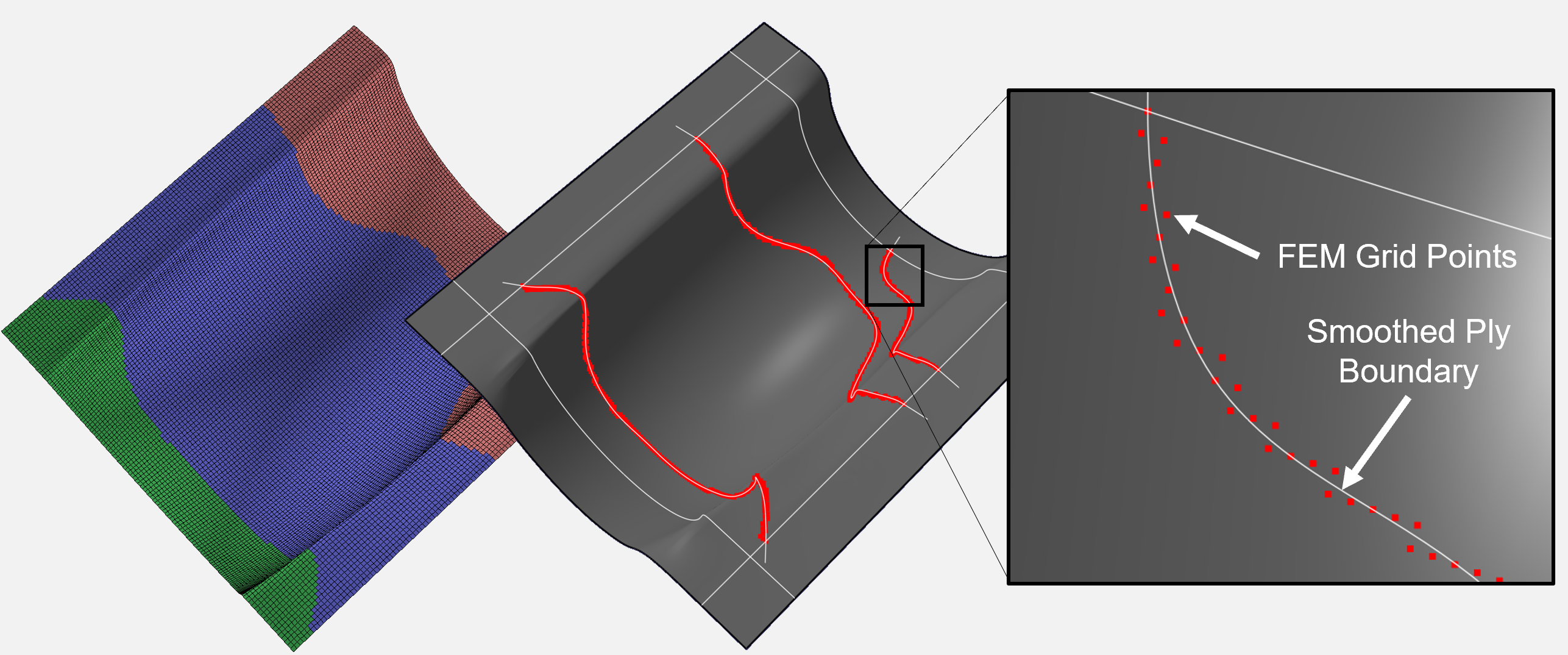

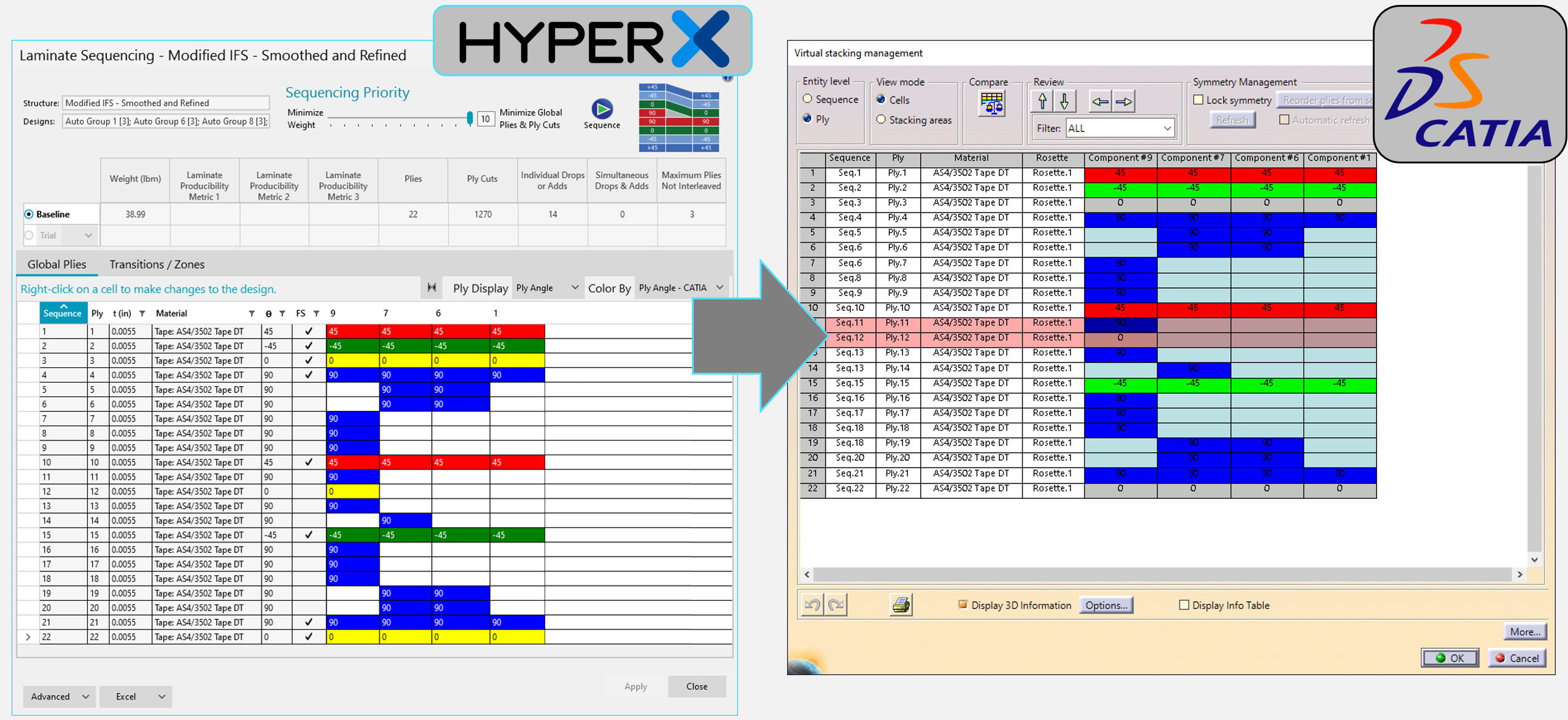

Fiber deviation is often introduced on structures with significant curvature because it is impossible to steer tows to achieve a desired uniform fiber orientation everywhere on the part without causing other defects such as wrinkling (local buckling) of tows. AFP process planners find fiber paths that are manufacturable, but may not line up with the original FEM fiber directions. HyperX can import fiber directions from VCP and iCPS software and include these fiber directions in lamina or laminate analysis.