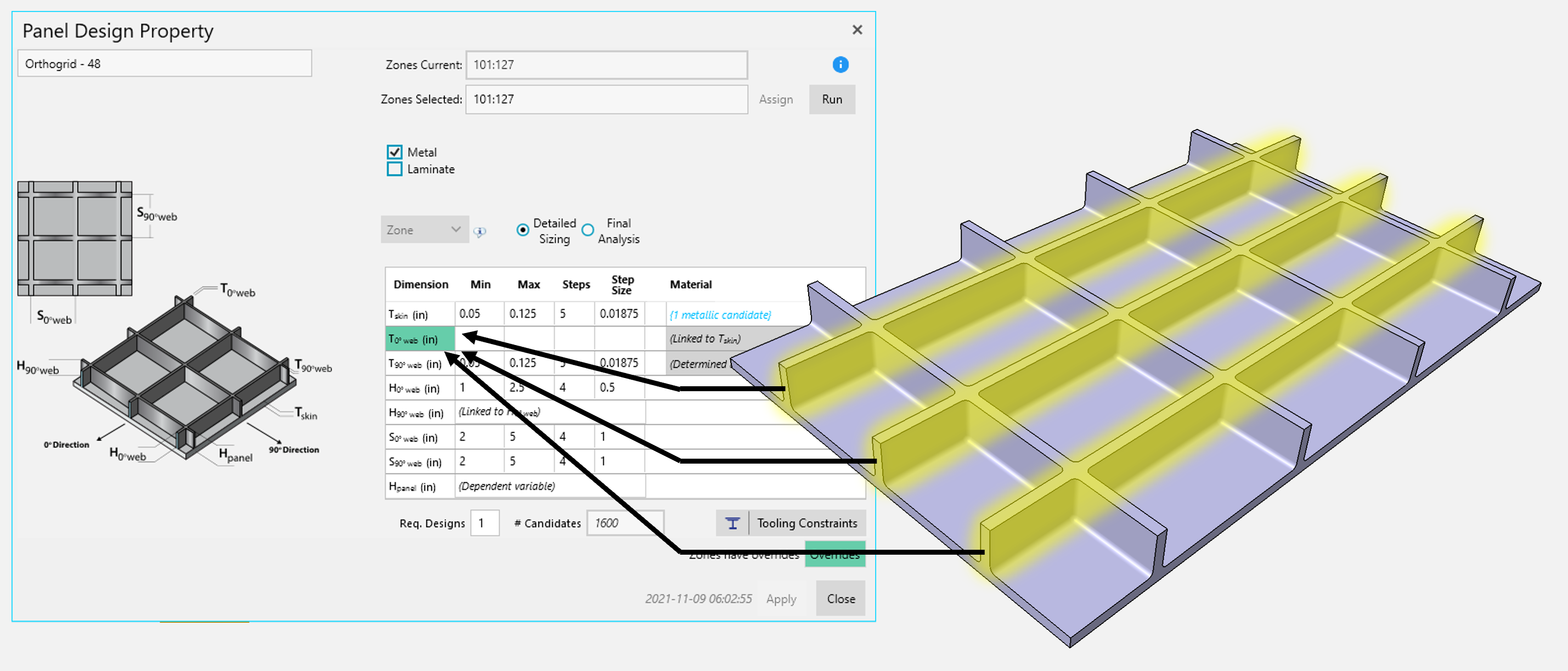

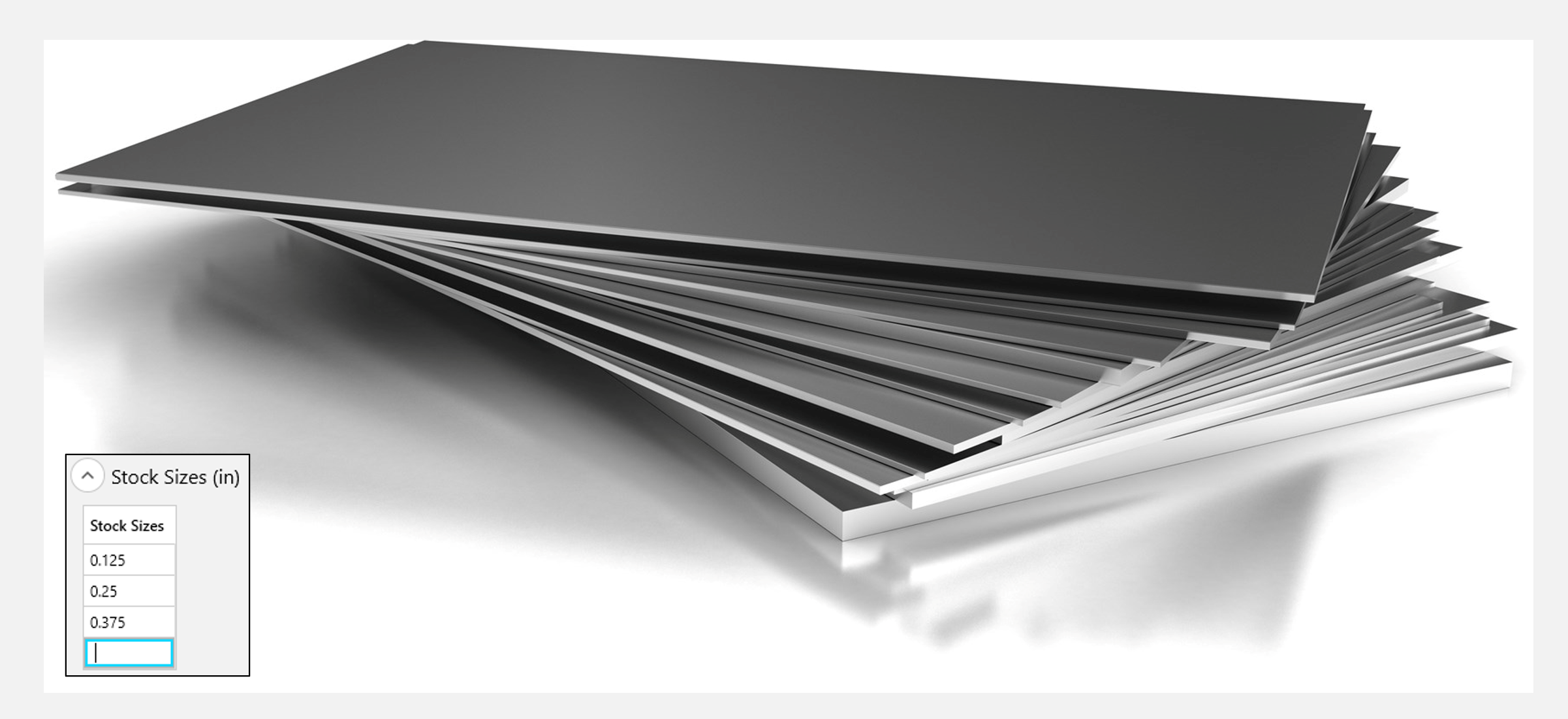

One challenge with analyzing machined structures is that the machining tolerance can result in structures that are slightly thinner than the nominal design. HyperX accounts for this feature by writing margins at the extremes of the specified tolerance to ensure that the structure has positive margins even in worse-case tolerance scenario.

During sizing of these panels, geometry checks can be enforced such as limiting the ratio of the stiffener height to thickness. This limit can be used to ensure that tall slender stiffeners will not flex during machining.

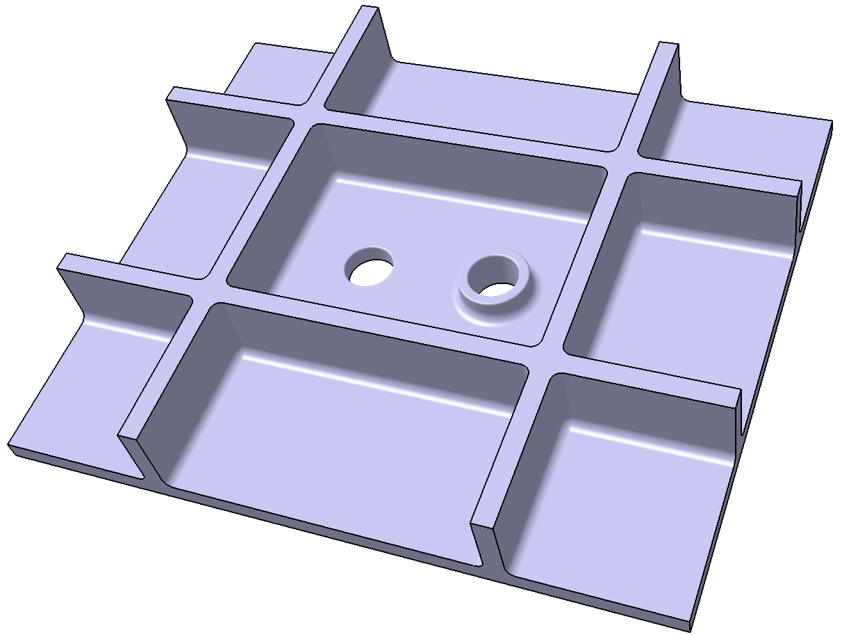

Lastly, holes are often added to machined structures to provide access for wiring or other systems. HyperX can determine the impact of these holes, with or without flanges, on the margins of safety during sizing.