HyperXpert: Design Insights

Capability Pages

Solution

HyperXpert resolves the challenge of quantifying the manufacturing variance impact on part weight by starting with – and going beyond – the HyperX-generated lightest design. Instead of showing only the one lightest-weight design, HyperXpert shows all possible designs that have a positive margin and provides an interface to compare these options in a meaningful way.

HyperXpert is, in general, a design of experiments (DOE) tool. Given a part surface and a defined design space (i.e. options for material systems, stiffener cross sections), as well as a set of failure criteria that a part needs to satisfy, this tool runs a full factorial DOE. In HyperX-terms, it uses the same HyperX solver to optimize designs to user selected failure criteria. For each of these workable solutions, a weight and relative producibility score (in terms of variance in design across the part surface) are calculated.

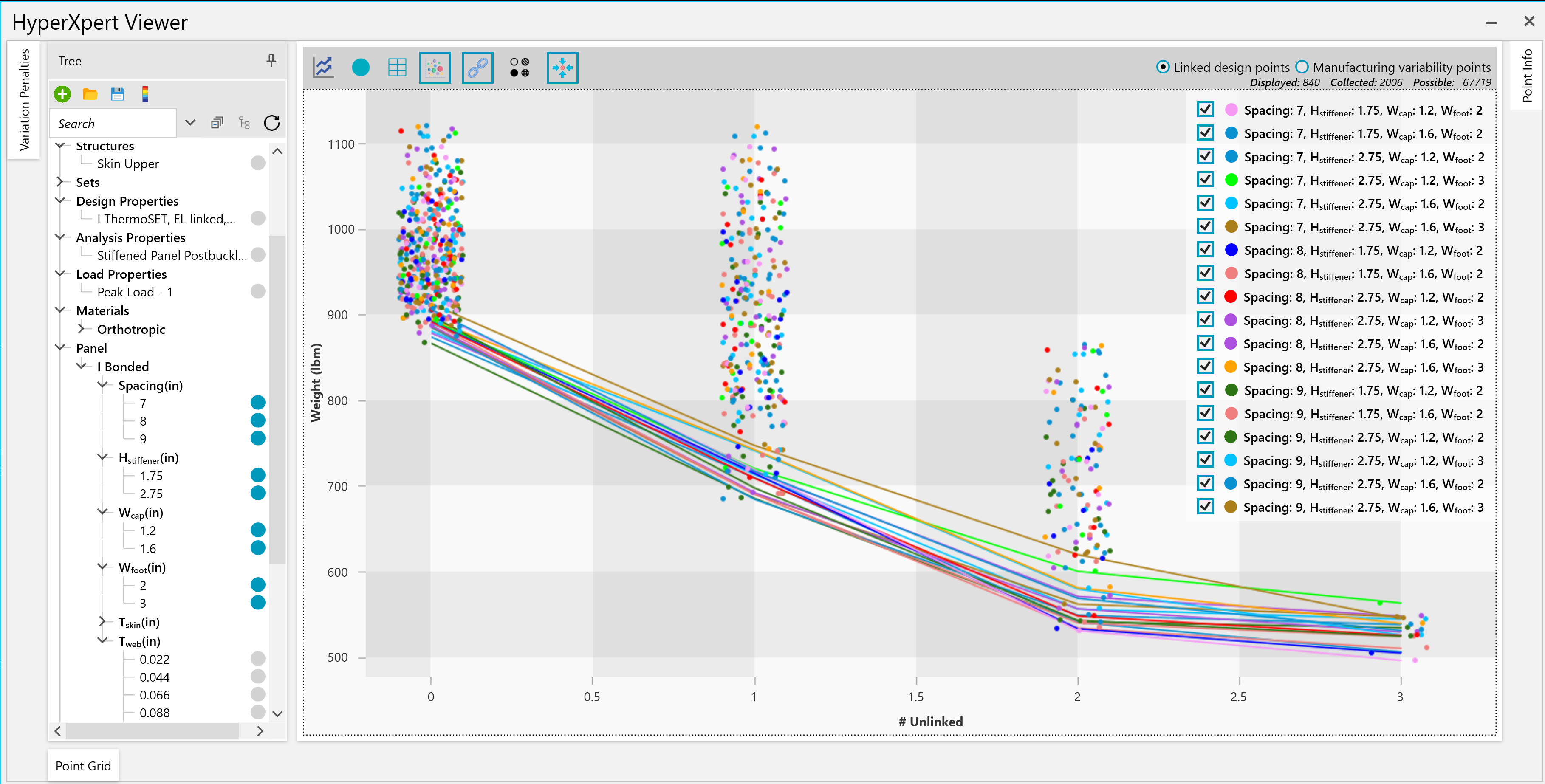

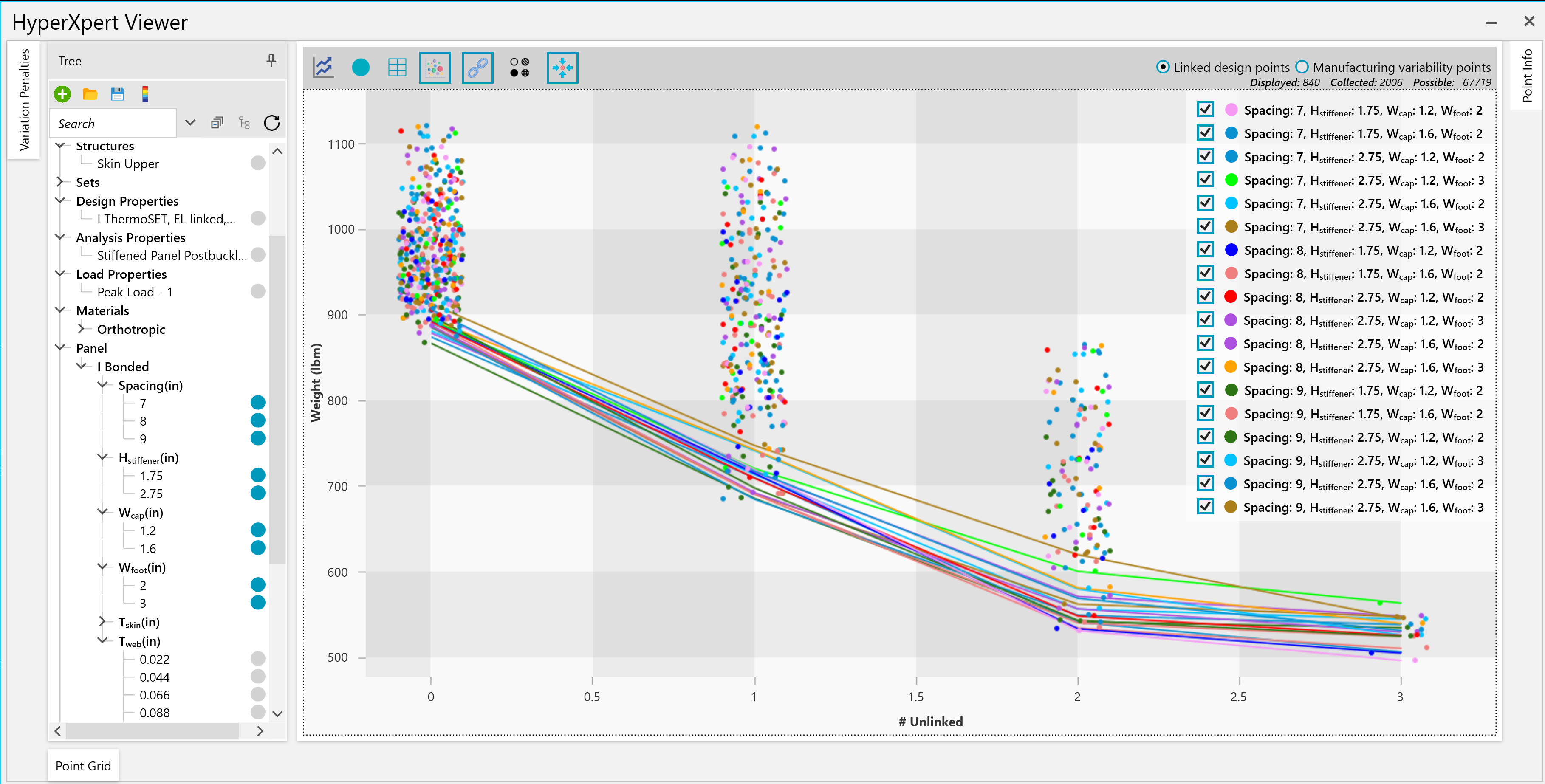

From here, the HyperXpert interface instantaneously displays the best viable options in the design space in a weight vs. variation plot. This plotting interface offers trendline creation, filtering, pareto frontiers, etc.; all of which serve to allow the engineer to glean meaningful design insights and use their own data-driven subjectivity to determine their “best” part design.

This powerful HyperXpert plotting interface is shown in the example above. Here, variation is quantified in terms of “unlinked variables.” A linked variable is a type and value that spans the surface of a part. That is, it’s the same value for all zones of the part. For example, a cross-sectional dimension such as stiffener height =2.75” that spans the length of the part. The more cross-sectional dimensions are linked across a part, the easier that part is to manufacture.

By plotting weight as a function of unlinked variables for the thousands of workable designs in the space, we can quickly understand that there is significant gain in producibility in going from 5 unlinked variables to 2 (i.e. ensuring that 3 dimensions are constant across the part), with a quantified weight penalty. These data driven insights provide you with valuable insights into design decisions such as stiffener tooling mandrels.

A key enabling capability of HyperXpert is its ability to pair variable links on the fly. By doing so you can reduce the number of viable design points to only those that have your selected data values linked. In this example, as toggled on in the tree, each individual Spacing value is paired with each individual Height value and with each individual Width of the cap and foot. This is akin to directly comparing stiffener mandrel shapes and their corresponding weight penalties.

Additional Resources:

Aerospace Structural Analysis and Design Optimization

Privacy

Site Terms

© 1995 - 2025 Collier Aerospace Corporation. All Rights Reserved.